Guardians of design

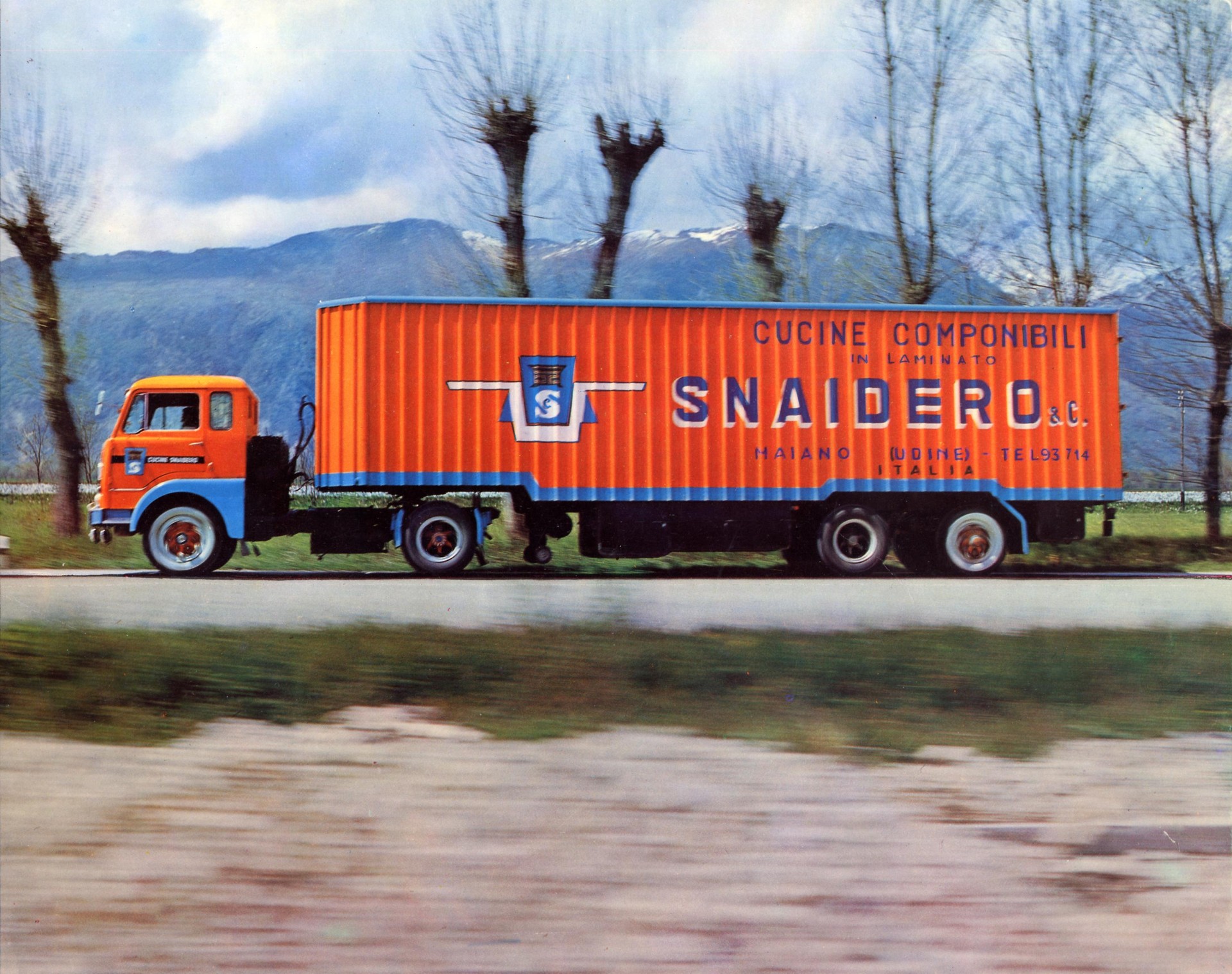

Since 1946 Snaidero means design, research and beauty.

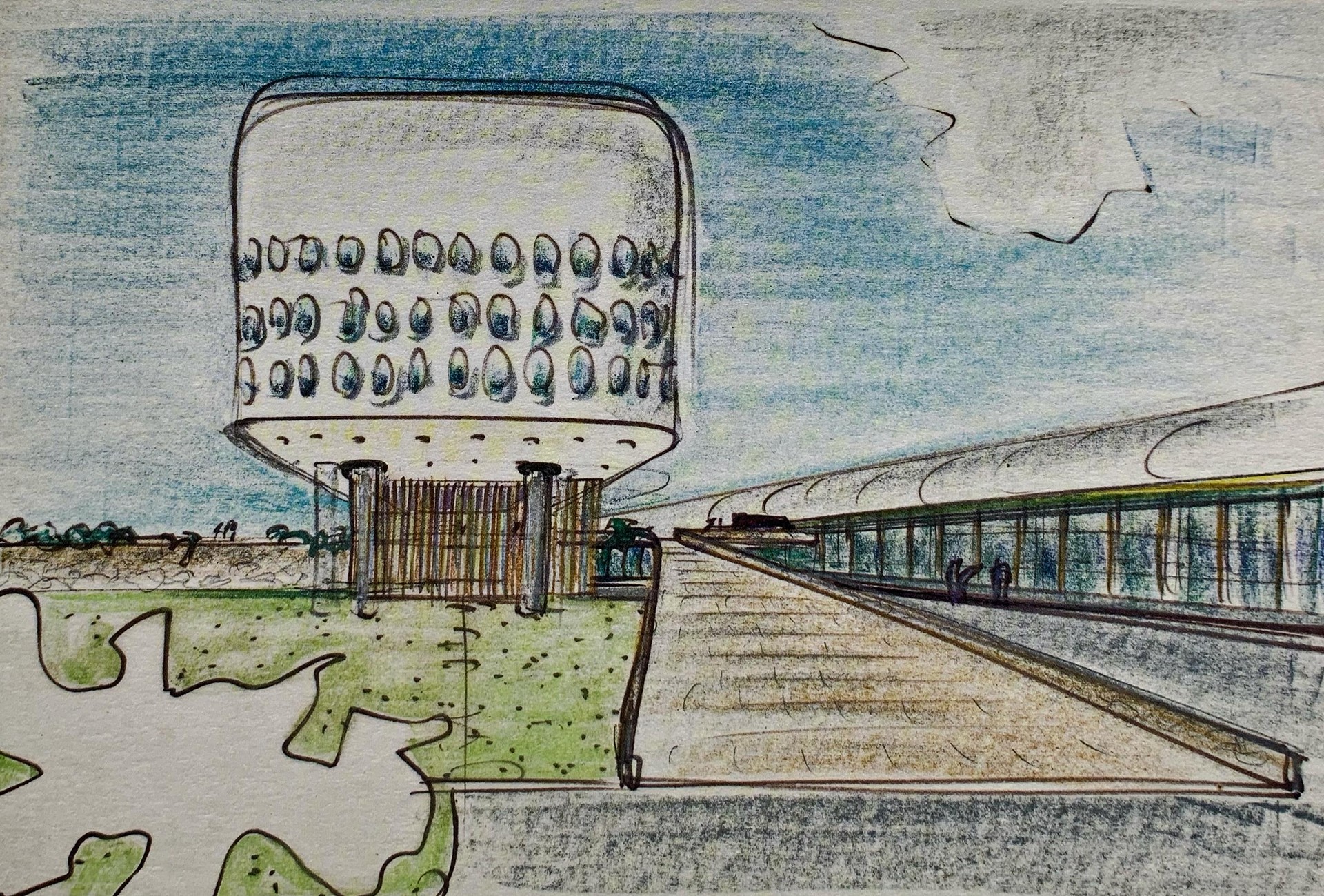

Among the green hills surrounding Majano and the historicity of the area’s medieval relics is Snaidero’s headquarters: a design temple for design designed by architect Angelo Mangiarotti.

78 years of enterprise

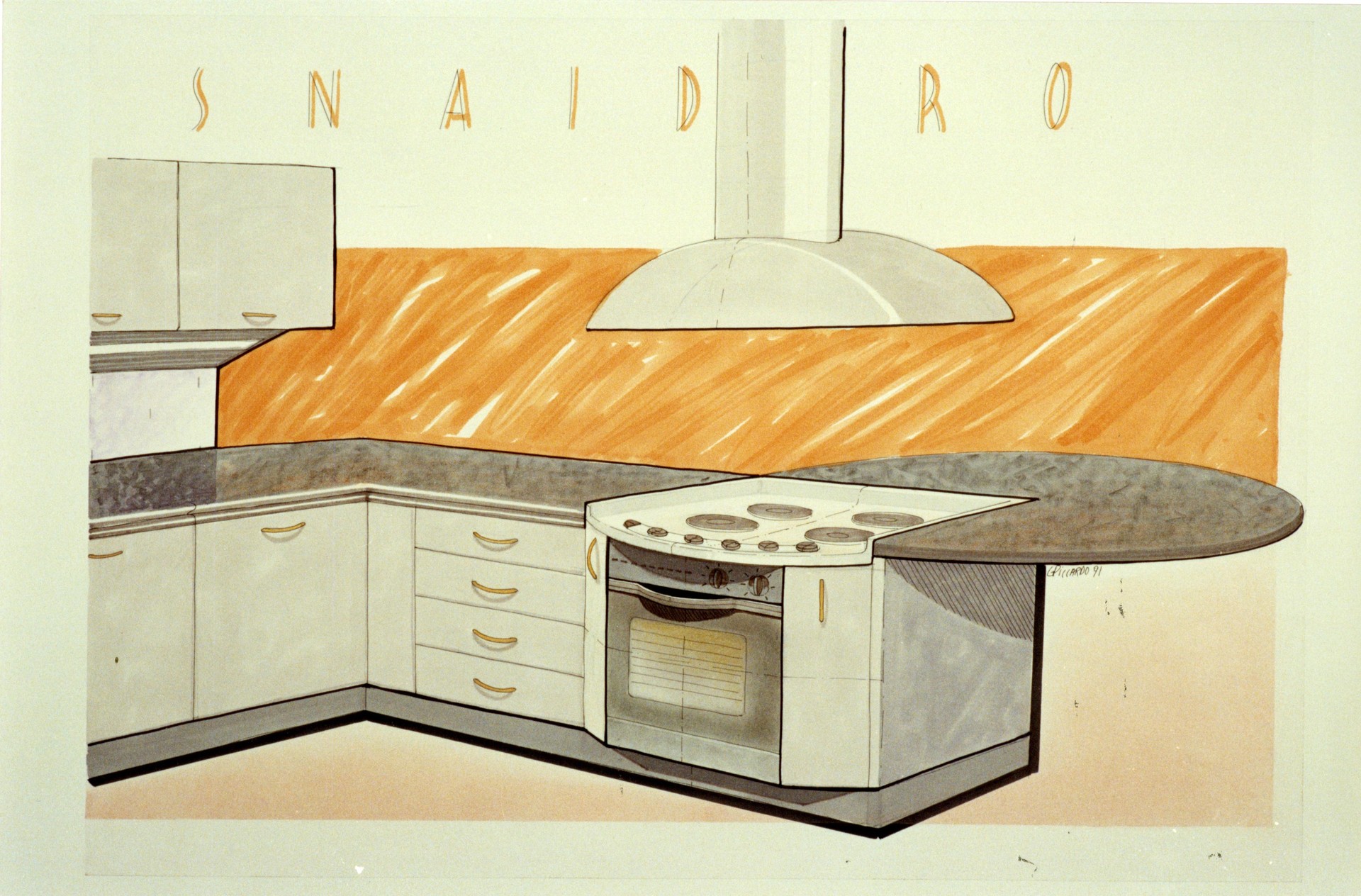

SNAIDERO COLLECTIONS

Design, Research and Beauty. Snaidero collections reflect each personality. The Icone collection kitchen characterise spaces with their distinguishing features. The Sistema collection allows for the utmost freedom of design.

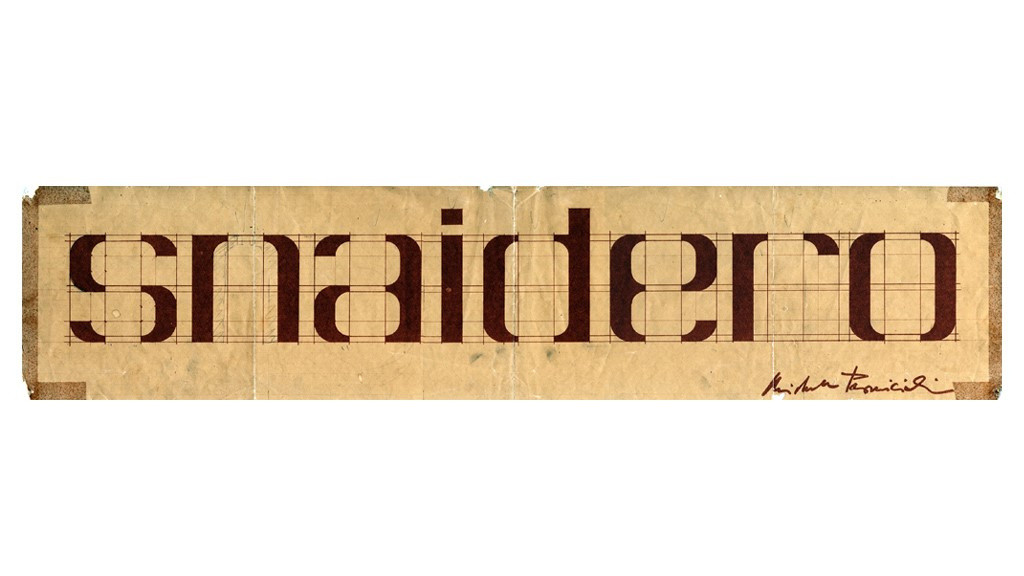

THE SIGN

Distinctive sign, exclusive collaborations, avant-garde. The Snaidero sign has always traced the history of Design kitchens.

BECOME PARTNER

For more than 50 years Snaidero has been exporting its contract projects around the world, and its kitchens are in the 500 points of sale spread over 5 continents. The value of its history and collections is sealed by exclusive collaborations.