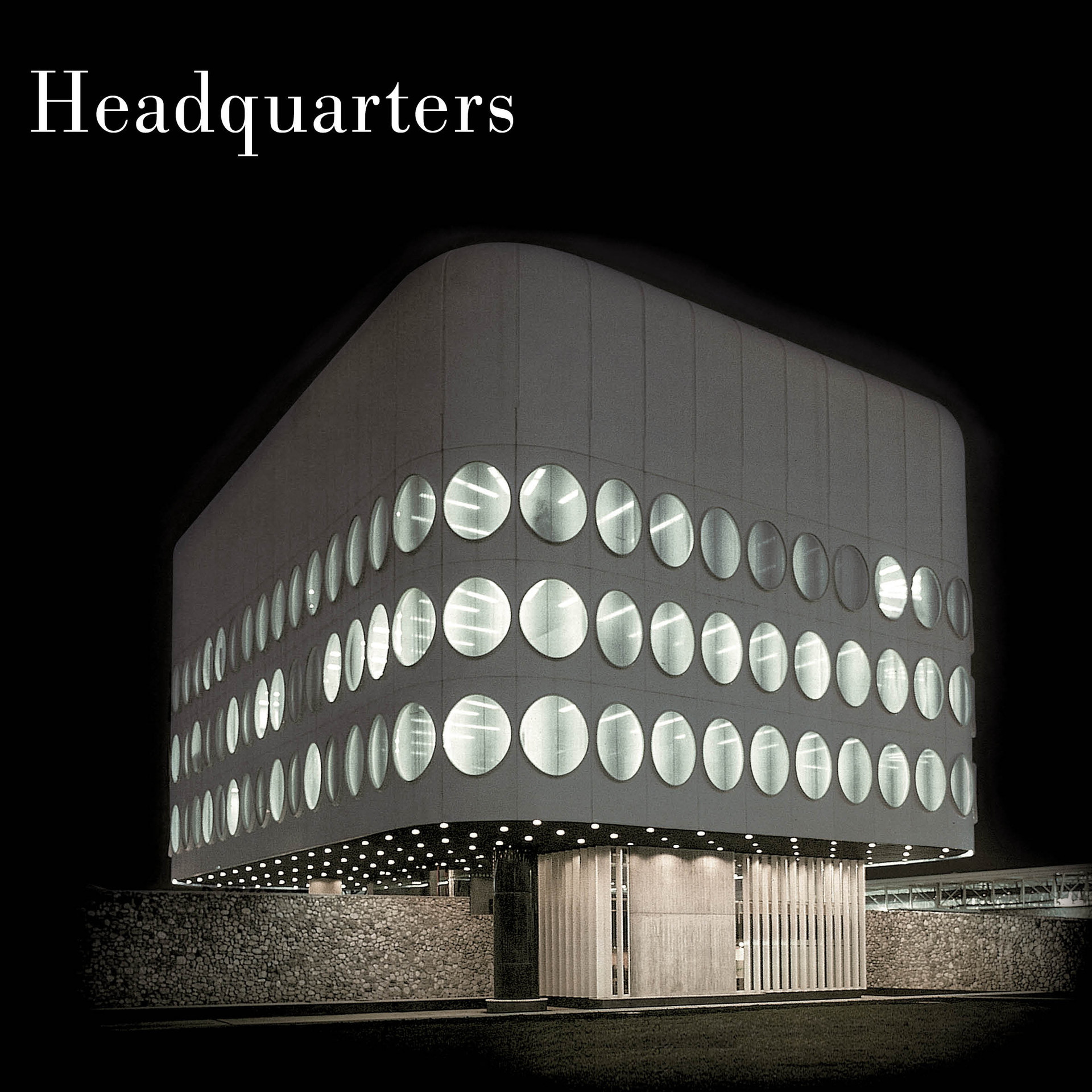

SNAIDERO SIGN

Distinctive sign, exclusive partnerships, avant-garde.

Snaidero has always made a mark on the history of designer kitchens.

Collections that are innovative in their shapes, technology and materials. Unwavering attention to processing, the desire to excel. Research that generates beauty.

The beauty of history, the beauty of courage, the beauty of pride

The beauty of Snaidero Collections

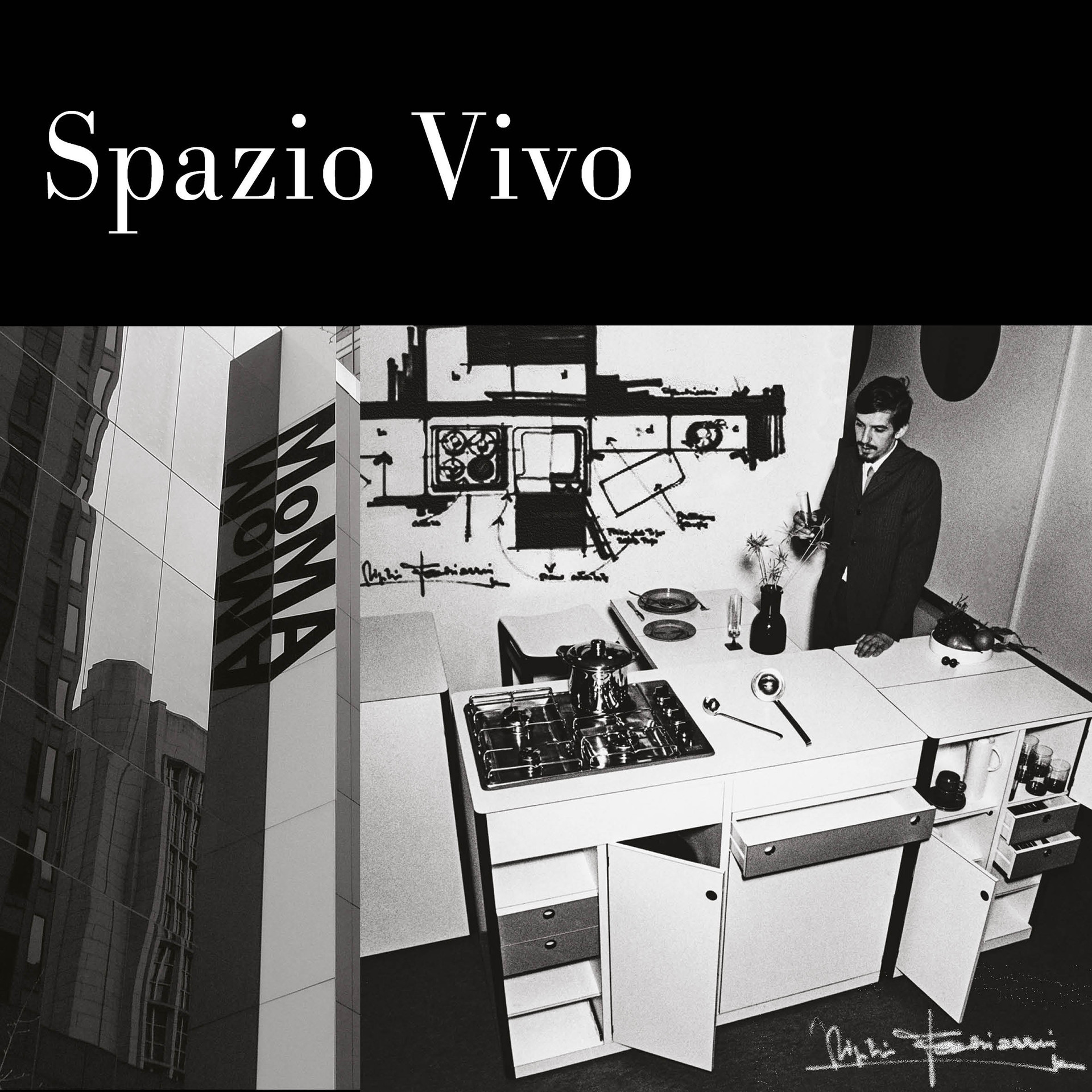

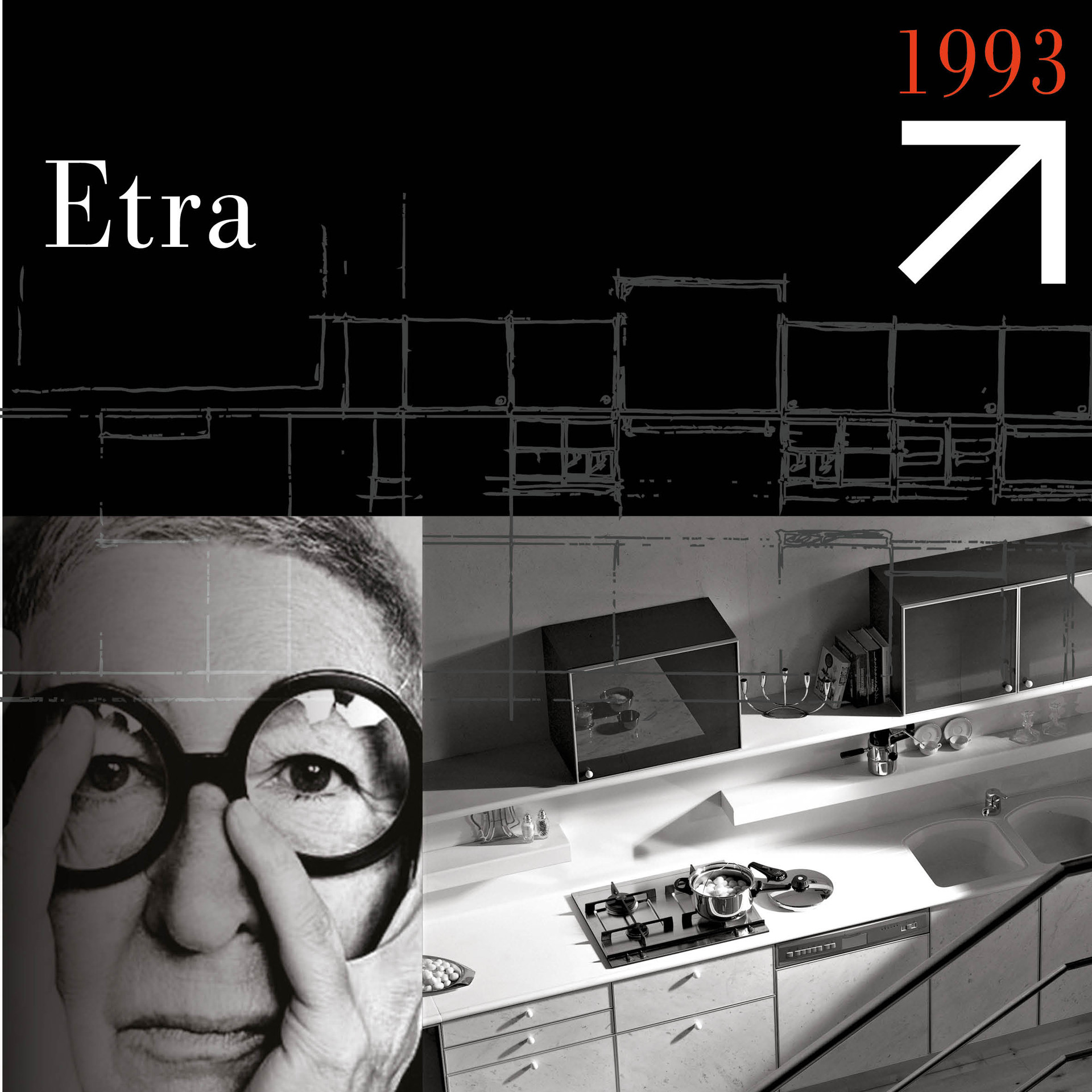

50 years of design

Italy discovers the modular kitchen, snaidero flies to moma in new york.

Roots and vision.

“Design should be a little behind. Behind the object, behind its result, to ensure a much longer life.”

Collaboration between snaidero and pininfarina begins: as a goal, the future.

“Architecture must give directions that can also apply to others, which must serve others to learn other things, as a kind of teaching of positive will.”

A timeless icon with style and personality.

Functional use of space. The center of daily life.

Universal design. Design spaces free of complexity, the product adapts to the individual user.

The idea of beauty.

The substance of form. Simple elegance.

The industrial response to a contemporary housing development.

Dedicated to those who love a sartorial definition of the kitchen environment under the banner of innovation and elegance.

PAOLO PININFARINA